Mechanical presses and other machines

Machines for machining

Measuring devices

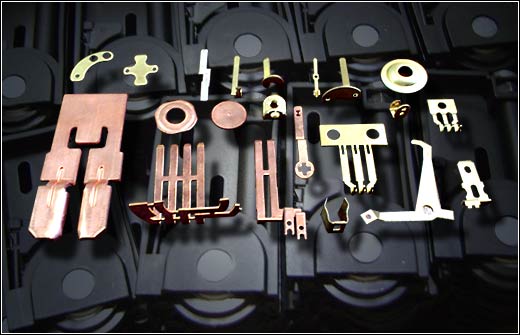

We produce punch and pressed details using mechanical and hydraulic presses and automatic tape feeders and uncoilers.

Materials that we use are mainly: carbon steel and acid-resistant tapes, cold and hot-rolled; colour metals (copper, brass, bronze, beryllium, aluminium, etc.)

Punching is conducted on technologically advanced progressive punching dies, which are designed and developed in our plant.

We have a several dozen experience in manufacturing punched and pressed details. We provide high quality details, we use fixed controls for engineering processes based on the PPAP lev3 requirements.

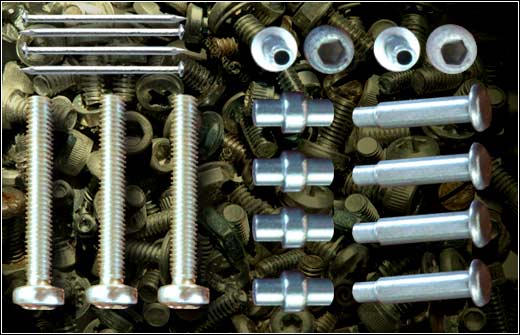

| Production method | By machining using CNC and traditional turning machines. | |

| Finishing | Polishing, anodizing, SandingPowder coating, vacuum plating, nickel, zinc, tin, silver, platings, etc. | |

| Tolerance | 0.01mm | |

| Material | Aluminium, copper, brass, stainless steel, iron, zinc alloy, etc. | |

| Quality control | ISO 9001:2008 i ISO/TS 16949:2009. | |

| Acceptable file formats | AutoCad (DWG, DXF), STP, PDF, JPG, BMP |

We manufacture forgings out of every type of steel and colour metals.

For each project, we create a unique forging line using purpose-designed tools.

Our engineers define the best usage of equipment, depending on the size of parts, weight and complexity.

The quality of forged elements is constantly monitored throughout the entire process and also during the final control.

|

|

|

Copyright 2014 © by AMF

|

Since 2013 year the company has a new

QMS certificate, ISO 9001:2008 ( _ more )

The service is provided in accordance with applicable standards and all statutory and secondary legislations and other company requirements.

The company's management support the

quality policy and provide means necessary to is implementation and to increase the efficiency of the quality

management system

and environment

management

system.